No-Dig Rehabilitation of Pipes with Close-fit Technologies

CF Liner

The polyethylene liner tube used for the process is formed into a C shape during production and transported to the site on a roll.

The C-shaped pipe profile allows easy insertion of the liner pipe into the pipe to be renovated. The liner pipe is thermoplastically re-formed. The end result is a tight-fitting liner pipe, with standard components available for installation and commissioning.

| System | pressure |

| Transported Medium | potable water, gas, sewage, industrial waste water, rainwater |

| Host Pipe material | steel, cast iron, azbestos cement, KG PVC, reinforced concrete, KM PVC |

| Diameter | 100-500 |

| Shape | circular |

| Pressure | 1-10 |

| Fabrication | PE liner |

| Comment | close-fit, can be installed as a self-supporting or interactive liner |

Rolldown

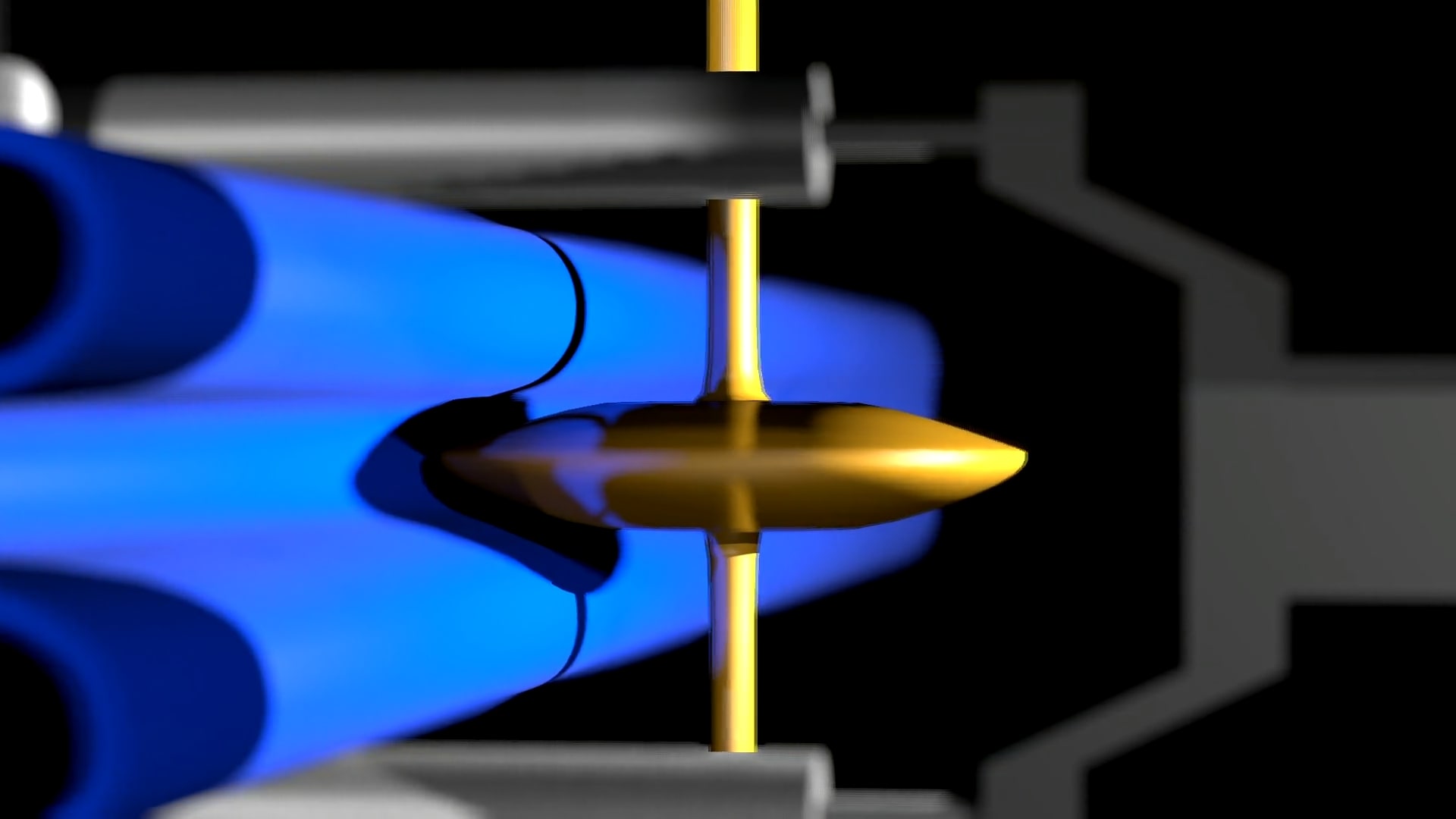

Rolldown uses standard PE pipe to create a close-fit liner within an existing pipe and is specifically designed for the lining of the pipe diameters up to 500mm. It can be designed and installed as a stand-alone, fully pressure-rated pipe, or as a thin-wall lining to eliminate leakage in an otherwise sound pipe. The PE liner pipe is pushed through roller sets which reduce the pipe diameter concentrically, typically by about 10%. The pipe is retained naturally at its reduced diameter for later/separate installation. Once installed, the reduced diameter pipe is pressurized allowing it to revert back towards its original size, forming a close fit within the host pipe which minimizes loss in cross-sectional area and maximizes capacity.

We carry out the installation in close cooperation with Subterra.

| System | pressure |

| Transported Medium | potable water, gas, sewage, industrial waste water, rainwater |

| Host Pipe material | steel, cast iron, azbestos cement, KG PVC, reinforced concrete, PE |

| Diameter | 100-500 |

| Shape | circular |

| Pressure | 1-16 |

| Fabrication | PE liner |

| Comment | close-fit, can be designed as structural or semi-structural liner |

Subline

Subline is a well-proven technique that uses standard polyethylene (PE) pipe to create a close-fit liner within an existing pipe. It is specifically designed for thin-wall lining applications currently in diameters of up to 1600mm.

In the Subline system the PE liner is pushed through a former which folds it into a ‘C’ shape which is held in space by strappings. This reduces the overall pipe cross section by approximately 40% and creates a clearance for quick, easy installation into the host pipe using standard sliplining techniques. Once installed the folded pipe is pressurized to snap the strappings and allowing it to revert back to its original shape, to form a close-fit within the host pipe.

We carry out the installation in close cooperation with Subterra.

| System | pressure/gravity |

| Transported Medium | potable water, gas, sewage, industrial waste water, rainwater |

| Host Pipe material | steel, cast iron, azbestos cement, KG PVC, reinforced concrete, PE, concrete, clay, brick |

| Diameter | 100-1600 |

| Shape | circular |

| Pressure | 1-16 |

| Fabrication | PE liner |

| Comment | close-fit thin-wall lining system |